When you touch a handmade garment do you notice its different texture compared to store-bought clothes? The secret usually remains hidden because most people overlook the seams. The unsung heroes of sewing practice Nahttypen seam types decide which appearance your sewing project will achieve.

The wrong seam type causes your dress to miss the right drape and your shirt to break after three washes. Don’t worry—you’re not alone. Even experienced sewers make incorrect choices which results in them losing time and wasting fabric while they experience frustration.

You will learn which seam suits your fabric best and you will discover how to prevent common garment mistakes and you will receive practical advice which helps your projects achieve a boutique appearance.

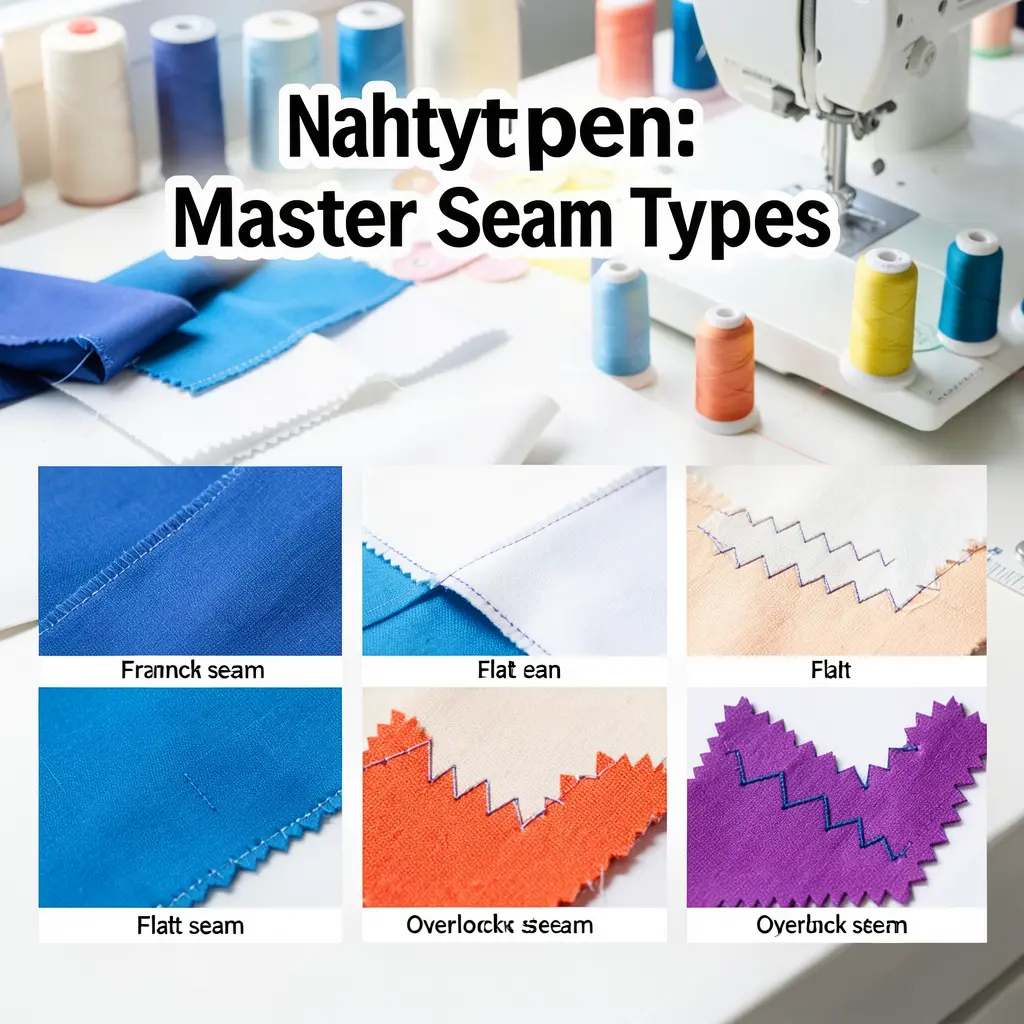

What Are Nahttypen (Seam Types)?

The term Nahttypen describes different seam types which show how fabric parts connect with each other. Seams form the essential base for all sewn products because their presence allows designers to construct their items.

The seam functions as the point where two or more fabric layers come together to receive stitching. The existence of seams creates an additional challenge for designers who create stitched products. Three key elements of your selection process get determined through your selected type which includes durability as it determines product lifespan and appearance assessment as it determines visual appeal and comfort assessment as it determines skin contact experience.

ISO 4916:1991 establishes eight main seam classes which people use for sewing throughout the globe. Designers use the plain seam for basic pillowcase construction while French seams serve as the advanced stitching technique for high-end fashion clothing.

Your fabric choice matters hugely here. The construction of a lightweight chiffon dress requires different seam types than the construction of heavy denim jeans. The application of an incorrect seam to delicate fabric results in fabric distortion through excess material and creasing. The usage of a weak seam on jeans allows the fabric to tear when the person performs a squat.

Why Choosing the Right Nahttypen Matters

The lesson became clear to me when my 12-hour effort to create a linen summer dress resulted in seams that started to fray after my first laundry cycle. The use of basic plain seam stitching resulted in fabric waste because I did not finish the seam edges. The fabric cost for this project amounts to 45 dollars.

Seams require proper types because they provide three essential benefits. The first function of this system provides strength to the garment because it lets you wash and wear and move without losing its structural integrity. The flat-felled seam production standard enables jeans to achieve a lifespan that reaches multiple decades because it provides better endurance than other seam types.

The second element determines how comfortable the product becomes. Have you ever worn a shirt whose seams caused your skin discomfort? The problem happens when people choose a thick seam element instead of better options which need a flat seam design. The flat seams in athletic clothing exist because professional garment makers want to create clothing that will not cause skin irritation during physical activity.

Professional appearance gets determined by three crucial elements. A French seam on a silk blouse creates an expensive appearance through its elegant design. A visible, unfinished seam screams “homemade” in the worst way. The difference between a garment you’re proud to wear and one that sits in your closet often comes down to seam selection.

Project requirements determine which methods to use. A quilt requires seams that maintain a flat appearance while preventing bulkiness. A winter coat needs strong seams that can handle the weight of heavy fabric. Seams in children’s clothing must resist damage from active play and endure multiple wash cycles.

Flat Seams: Versatile and Comfortable

My preferred choice for athletic clothing and undergarments is flat seam construction. The seams maintain a flat appearance because they contact the fabric surface without creating any bulges or raised areas.

The process operates by using special stitching techniques to join two fabric edges that you need to place together without overlapping. The result produces a central seam that creates an even surface on both fabric sides without causing any skin discomfort.

The optimal applications for this material include T-shirts activewear yoga pants underwear and baby clothing. The product functions as a protective barrier for delicate skin which requires unrestricted movement. The use of flat seams for running shirt production results in a comfort improvement that shows clear contrast to using standard seams.

The fabric provides users with comfort because it does not create weight while allowing users to stretch their body movements. The fabric maintains its professional appearance when viewed from both its front and back.

Users need specialized equipment because standard sewing machines cannot handle the process which requires both a serger and a coverstitch machine. The process needs users to practice until they reach proficiency while it remains impossible to use with woven materials.

The technique requires users to learn the initial steps before they can master the system. The fabric edges need exact alignment because any 1mm variation will create a visible error. The process becomes a source of addiction after you achieve good results with flat seams. My knit projects now use flat seams for 80 percent of my work.

French Seams: Elegant and Durable

High-end dressmakers use French seams as their most effective construction technique. The technique securely protects all unhemmed fabric edges through the seam which produces a pristine appearance throughout both the external and internal sections of the garment.

This double-stitched method works like this: you first sew with wrong sides together (yes, wrong sides—this feels backwards at first), trim the seam allowance to about 1/8 inch, then fold and sew again with right sides together. The raw edges get trapped inside, invisible from both sides.

Best uses: Sheer fabrics like chiffon, organza, and silk where regular seams would show through. It suits unlined jackets and delicate blouses and all other clothing items which require equal visual quality for their interior and exterior parts.

The special stitching method provides two important advantages because it uses double stitching which creates extreme strength and total protection against fraying while maintaining an attractive appearance that conceals all unhemmed material.

The special stitching method provides two important advantages because it uses double stitching which creates extreme strength and total protection against fraying while maintaining an attractive appearance that conceals all unhemmed material.

The special stitching method requires extra fabric because it requires wider seam allowances which make garments heavier and take more time to complete than basic seam designs.

The special stitching method requires extra fabric because it requires wider seam allowances which make garments heavier and take more time to complete than basic seam designs.

A word of caution: French seams work beautifully on lightweight fabrics but become chunky on anything heavier than cotton lawn. I made that mistake with a denim jacket once—the seams looked like ropes. Delicate materials give you excellent outcomes.

Overlock Seams: Clean and Professional

The process requires you to enter any clothing store and turn a clothing item inside out. The finished edges show neatness because they appear to have been wrapped with thread by a professional. An overlock seam functions as the industry standard because it provides good performance.

Overlock seams (also called serged seams) do three things simultaneously: they stitch the seam, trim excess fabric, and wrap the raw edge in thread to prevent fraying. The machine functions like an entire sewing assembly line because it combines multiple operations into one unit.

Best uses: The material works best for knit fabrics T-shirts and stretchy garments which require both fast production times and strong construction. Most commercial clothing uses overlock seams because they’re fast, strong, and look professional.

The advantages of the product include two main benefits because it enables users to complete work faster and protects against fabric damage while providing a professional appearance which works with various materials.

The product requires users to acquire a serger machine which costs between $200 and $800 and uses more thread than conventional sewing methods while making it challenging to remove mistakes through stitching.

A user needs to learn more about sergers than about standard sewing machines because it requires them to handle four spools instead of one. The system allows you to complete your work twice as fast after you master it. I used a timer to record my time which showed that I needed 45 minutes to create a basic T-shirt on a standard machine but only needed 20 minutes with a serger.

Zigzag Seams: Stretchy and Functional

Zigzag seams become your essential solution when you lack a serger. The system operates effectively through your existing equipment because it functions as a dependable workhorse which performs its tasks.

The zigzag stitch operates through a needle which moves in two directions while it performs forward stitching to create a zigzag pattern. The built-in “give” system allows a seam to stretch without breaking which becomes essential for knit fabric use.

Best uses: Knit fabrics on a regular sewing machine, edge finishing to prevent fraying, stretchy garments, repairing seams that need flexibility.

The system works with any sewing machine because it enables seam stretch while stopping fabric from fraying and it functions with multiple types of materials.

Overlock seams produce a cleaner finish than this system which results in a less organized appearance that depends on proper tension adjustment but requires higher thread consumption.

The zigzag width and length settings need adjustment according to your chosen fabric. For jersey knit, I use a width of 4mm and length of 2.5mm. For woven fabrics that just need edge finishing, I go narrower—width 2mm, length 2mm. You should perform tests on scrap materials before you start.

The most common error that beginners make involves them pulling the fabric while they sew. The machine should handle all work while you need to steer the fabric through your hands. Your only responsibility is to control the fabric movement.

Plain Seams: Simple but Essential

The basic seam functions as the main starting point for all people while I continue to use it as my primary sewing method. The procedure requires you to position two fabric pieces with their right sides facing each other before you need to sew along the fabric edge and then open it up for pressing. The process requires only these two steps.

Best uses: Shirts, skirts, trousers, quilts, basically any straightforward sewing project. It’s the foundation seam type.

The beginners find it easy to use this method because they can apply it to almost all fabric types which requires only a short time to complete and simple modifications to be done afterward.

The sewing method needs edge finishing to stop fabric edges from fraying and it creates extra weight which will occur when the fabric completes the pressing process and the method cannot work with transparent materials.

The secret to professional-looking plain seams? Pressing. I cannot stress this enough. The process requires you to sew the seam followed by immediate seam pressing to make it flat. The subsequent procedure requires you to press the material until it reaches a complete open position. The single step transforms a $20 homemade skirt into a $100 boutique product.

The process of finishing edges holds importance in this situation. The raw edges need protection through pinking shears or a zigzag stitch or bias binding because these methods will prevent fabric fraying. Your seams will develop a fuzzy beard appearance after three washing cycles if you fail to complete the required process.

Flat-Felled Seams: Tough and Long-Lasting

People frequently ask about the reason behind the long-lasting nature of high-quality jeans. Flat-felled seams are the answer. The garment shows these extremely durable seams at its exterior through double stitching lines which run along the jeans side seams.

The construction process requires more work than other seams. The process starts with plain seam sewing followed by trimming one seam to 1/8 inch before folding wider seam allowance to cover the trimmed section while topstitching the enclosed area. The process appears difficult because it creates a product which can withstand almost any force.

Best uses: Jeans work shirts heavy-duty garments all items which require maximum strength.

The product features two advantages because it creates extremely strong double seams which completely hide raw edges while delivering a professional athletic appearance that works best with heavyweight fabrics.

The process requires many hours of work because it needs exacting folding and pressing methods while its results create visible exterior stitching on the clothing.

I use flat-felled seams for every pair of jeans I make. Yes, they take 3x longer than plain seams. The jeans from that period continue to function properly after five years while fast fashion machine sewed jeans from retail stores only survive for one season.

Common Mistakes to Avoid

The main mistakes which follow will help you avoid spending excessive time on your work.

Beginners choose inappropriate seams because they lack knowledge about fabric requirements. Beginners make two mistakes when they try to sew French seams with denim fabric and flat seams with woven cotton fabric. Fabric weight and stretch characteristics determine which seam should be used.

The pressing process should not be skipped. You need to press every seam right after you finish sewing it. The fabric will appear inexpensive because you did not press your material. Press your fabric during the sewing process instead of waiting until you complete your entire project.

People make mistakes with seam allowances because they do not understand their purpose. Patterns use seam allowance specifications to guide designers. Your garment becomes 7/8 inch larger when you mistakenly sew at 1/2 inch instead of 5/8 inch. Students have destroyed fitted dresses because this method exists.

Not finishing raw edges. This one drives me crazy. Your beautiful creation will break during washing because uncompleted seams destroyed your work. The process takes five minutes. The process protects the entire garment.

Sewing with out-of-date needles makes your sewing process difficult. A blunt needle will result in two problems because it causes stitch skipping and fabric bunching. A universal needle on knit fabric will create holes. The sewing process requires needle changes every eight hours for each new project while matching stitches with fabric types.

Sewing over pins. This practice results in broken needles and machine destruction while producing hazardous metal debris. You should either remove pins during your sewing process or position them at a right angle to your stitching path.

Best Practices for Perfect Nahttypen

Do you want your seams to achieve their best appearance? You need to implement these methods because they differentiate professional sewers from regular hobbyists.

You should perform your initial tests on scrap material. You should always conduct your tests for seam and stitch length and tension settings on a scrap piece of your actual fabric. The 30-second process prevents you from needing to spend hours to fix sewing mistakes.

You need to purchase essential tools for your work. The proper tools for your work include sharp fabric scissors which you should only use on fabric plus high-quality thread which must match the weight of your fabric and suitable needles and an effective iron. The items in this list serve as fundamental requirements for your work.

You should select thread that matches your fabric color. The correct thread materials require cotton thread for cotton fabric and polyester thread for synthetic materials and serger thread for overlock seams. The incorrect thread usage results in both puckering and thread breaks.

You must control your tension settings. You should change the tension settings until both sides of the stitches achieve the same appearance. You should conduct tests on scrap material until both sides achieve the same appearance.

You need to start your seams with backstitching and end with backstitching. Backstitching on your seams helps to secure them against unraveling. You need to sew forward one centimeter then backstitch until you reach the edge before you continue sewing forward. You should repeat this process for your ending point.

You should grade your seams when working with heavy fabrics. You should trim each seam allowance of your multiple layers to different widths. The procedure helps to decrease bulk while improving the flat appearance of the garment.

You should select closed seams for your unlined clothing. French seams and flat-felled seams and bound seams provide excellent edge finishing solutions because they hide raw edges when no lining exists to cover them.

FAQ

What does Nahttypen mean?

Nahttypen is German for “seam types” and refers to the different methods of joining fabric pieces together in sewing. The term encompasses various techniques from simple plain seams to complex French or flat-felled seams, each serving specific purposes based on fabric type and garment requirements.

Which seam type is strongest?

The most robust seam type exists in flat-felled seams which require two stitching lines to completely cover all seam areas. The reason for their application on jeans and workwear exists here. The second strongest seam type is French seams because they use two stitching lines to secure all unrefined edges within the seam structure.

Can I use regular seams on stretch fabric?

Not recommended. Stretch fabrics need seams that stretch with them—otherwise, the seam will snap when the fabric stretches. Use zigzag seams, overlock seams, or flat seams with stretchy stitches. A straight stitch on knit fabric breaks easily.

Do I need a serger for professional-looking seams?

The simulation does not require actual vital signs to operate. People can reach professional results through basic sewing machines which enable edge finishing via zigzag stitches and proper seam selection. The use of sergers provides speed and better results, yet they remain optional for achieving high-quality outcomes.

How do I stop seams from puckering?

Check four things: tension (adjust until stitches look even on both sides), needle (use sharp, appropriate size), thread quality (cheap thread causes problems), and pulling (don’t pull fabric while sewing—let the machine feed it naturally). Also, press seams immediately after sewing.

What seam allowance should I use?

You need to follow your pattern specifications because they require specific seam allowances. The standard sewing allowances for different items are 1/2 inch which tailors to quilts, 5/8 inch which serves for garments and 1/4 inch which applies to narrow seams. The final size will change when you modify the allowance because the pattern remains unmodified.

How often should I change my sewing machine needle?

You should replace needles after finishing each project or after using the sewing machine for eight hours. Dull needles create skipped stitches and puckering problems, which can result in fabric destruction. The user must replace the needle when it contacts a pin or produces a popping sound.

Conclusion

Learning to master nahttypen enables you to experience satisfaction with your sewing work. The following information represents the most critical elements you need to know about the situation.

- Match seams to fabric—lightweight fabrics need delicate seams, heavy fabrics need strong ones

- Press every seam immediately—this single step makes amateur work look professional

- Finish raw edges—prevents fraying and extends garment life dramatically

- Practice on scraps first—saves time, fabric, and frustration

Begin your work using basic seam techniques which you will finish with zigzag stitching. After gaining proficiency in basic techniques you should learn French seams which suit delicate work and flat seams which are designed for knit fabrics. Before creating advanced flat-felled and bound seam techniques you must first master essential seam techniques.

Your next step? Choose one of the seam types which this guide presents and practice this seam on your fabric scraps. The process requires you to create samples which will help you test various fabrics while you develop your basic muscle memory. Your investment will provide returns through every project which you complete in the future.